Why safety checks are important for ready-made foods

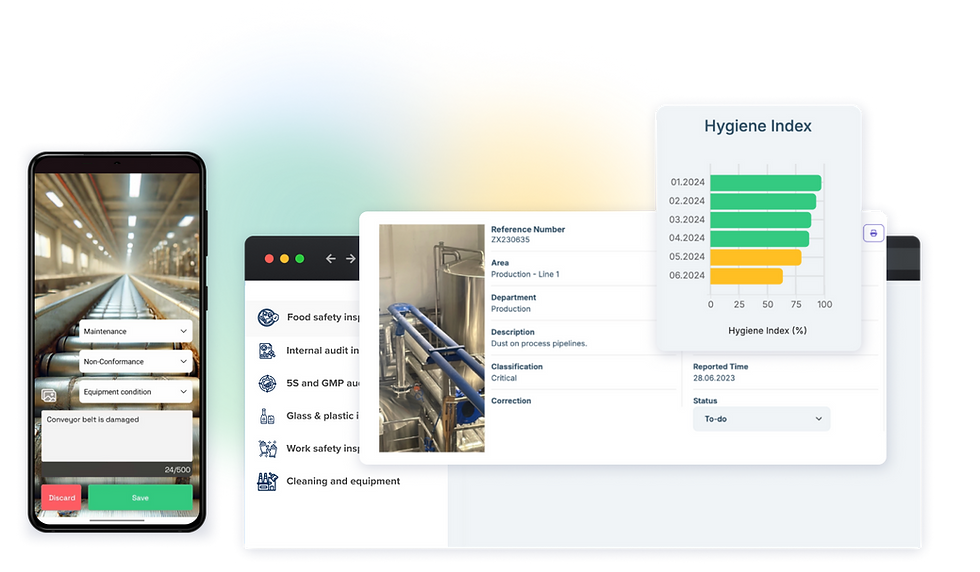

Safety checks in ready-made food production help prevent contamination and ensure your products are safe for consumers. Problems can happen at any stage, from ingredient sourcing to final packaging. Inspectle helps you manage every detail, ensuring your ready-made foods are always safe and high-quality.

Trusted by:

Make sure your ready-made foods are safe and fresh

Inspectle makes it easier to handle problems you encounter during routine daily operations and run things better. Here are some key points:

Start a free trial →

Automate Routine Checks

Inspectle automates routine checks, saving your team valuable time. Manual inspections can be slow and prone to errors. With Inspectle, checks are done on time and recorded correctly, reducing the workload and freeing up staff for other important duties.

Keep Your Team Organized

Inspectle helps you stay organized by tracking all quality checks and showing you what has been done and what still needs attention. In the busy world of ready-made food production, keeping track of everything is crucial. Inspectle makes it easy to monitor inspections and ensure nothing is overlooked.

Improve Your Safety Culture

Inspectle helps improve food safety culture in the ready-made foods industry by making it easier to follow safety protocols and keep track of important checks.

Get Started with Inspectle

To start using Inspectle for ready-made food quality management, sign up for a free demo or a trial. Our team will quickly help you set up your account. Then, you can begin your quality checks and see how easy it is to use Inspectle.

Imagine all you can do with Inspectle. Start for free.

No obligations. No credit card required.

Focused checks for better ready-made food production

We know your quality and production teams are busy. Inspectle Food gives you more focus time, allowing you to do quality and hygienc inspections with fewer distractions.

Storage Management

Inspectle tracks the condition of storage areas and ensures that all storage practices meet safety standards. This helps prevent spoilage and contamination, ensuring that all ingredients and finished products are stored safely.

Microbial and Chemical Safety

Inspectle helps monitor and document sanitation practices to ensure thorough cleaning, reducing the risk of microbial and chemical contamination. By automating routine checks and keeping detailed records, Inspectle helps maintain high hygiene standards.

Cross Contamination

Cross-contamination can occur when raw ingredients come into contact with cooked foods or when allergens mix with non-allergenic foods. This is a common issue in ready-made food production. Inspectle helps by automating and documenting thorough cleaning processes to prevent cross-contamination

Better Packaging Practices

Inspectle helps to confirm that packaging processes are properly monitored and recorded, maintaining the balance between product protection and sustainability. This reduces the risk of contamination from packaging materials.