Keep Food Packaging

Safe with Software

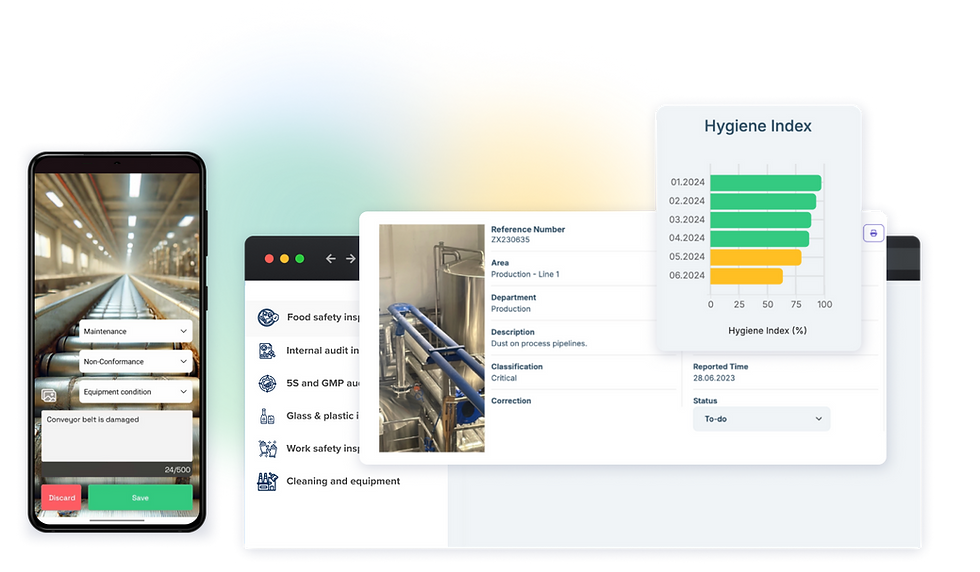

Keeping food packaging safe is important at every stage, from sourcing materials to sealing the final product. Each part must be carefully monitored to prevent contamination and protect food quality. Inspectle Food helps you manage these processes easily, saving time and maintaining high standards.

Why food packaging safety checks matter

Safety checks in food packaging are important to avoid contamination and make sure the packaging protects the food properly. Issues can occur at any stage, from getting materials to sealing packages. Inspectle helps you handle every detail, keeping your packaging safe and high-quality.

Trusted by:

How Inspectle Food helps you

Inspectle provides many benefits that address the specific challenges of quality and production teams in the food packaging industry, helping to improve overall operations:

Automate Routine Checks

Inspectle Food makes it super easy to do and track digital hygiene and cleaning checks to make sure all equipment is properly sanitized, reducing the risk of contamination.

Employee Training and Education

Poor employee awareness of food safety is one of the leading causes of costly non-conformities for the packaging industry. Because of Inspectle Food's simplicity – everyone can visually track and understand food safety.

Regulatory Compliance

The food packaging industry must comply with various safety standards and regulations. Keeping up with these requirements can be difficult and time-consuming. Inspectle helps by providing easy access to compliance checklists and making sure that all regulatory standards are met.

Get Started with Inspectle

Ready to take the stress out of your quality checks? Our team will help you set up everything quickly. Use Inspectle Food to rebuild your food safety culture and see how easy it is. Get started for free.

Focused checks for better food packaging

We know your quality and productions teams are busy. Inspectle gives you and them more focus time, allowing you to conduct quality, maintenance and hygiene checks with fewer distractions.

Consistent Quality Control

Maintaining consistent quality control across all packaging lines can be challenging, leading to variability in product safety and quality. Inspectle provides tools for regular quality checks, helping to standardize processes and maintain high standards.

Avoid Cross-Contamination

Your facilities often handle multiple types of food products. Leading to risk allergens or pathogens from one product come into contact with another. Inspectle can help manage these risks by monitoring and documenting all processes, ensuring strict separation and proper handling protocols.

Safe Packaging Materials

Packaging materials can sometimes release harmful chemicals into the food, especially if they are not tested properly. Materials like plastics, metals, and inks used in packaging can contain substances that migrate into the food, causing contamination. Use Inspeclte to ensure all packaging materials are regularly inspected and tested to prevent such issues.

Better Hygiene Practices

Keeping packaging equipment and facilities clean is critical to avoid contamination. However, some areas might be difficult to clean properly, leading to hidden spots where bacteria can grow. Inspectle helps by scheduling and tracking sanitation routines, ensuring thorough cleaning and maintenance.